Join our daily and weekly newsletters for the latest updates and exclusive content on industry-leading AI coverage. Learn More

As hyperscalers continue to invest in data center expansion to meet LLMs’ soaring computational and power demands, a Swiss startup is leading the charge to help them make the most of their existing infrastructure first.

Apheros has developed a novel metal foam that upgrades data centers’ cooling aspect, which accounts for nearly 40% of their total energy consumption. The technology can improve cooling systems’ heat exchange by 90%, thereby cutting down energy usage by a significant margin.

The company today announced $1.85 million in pre-seed funding from Founderful. It plans to use the capital to take its technology to more cooling system manufacturers and expand its reach to global data centers.

In the long run, it will also explore the application of these metal foams in other domains.

“There is a dire need for more efficient cooling solutions. AI development is driving exponential growth in data center energy consumption and inefficient cooling is the main culprit. Our unique metal foams have superior heat exchange and fluid transport properties, especially for liquid and two-phase cooling. With our customers, we are redefining thermal management,” Gaëlle Andreatta, co-founder and CTO of Apheros, said in a statement.

In recent years, data centers have faced mounting pressure to meet the computational demands of next-gen workloads, particularly AI training and inference. Unlike traditional workloads, AI applications—especially those using complex algorithms and deep learning models—demand specialized hardware like GPUs and TPUs. The shift to these resources is significantly driving up energy consumption, with Goldman Sachs estimating that data centers will consume 3-4% of the world’s power by the end of the decade—up from the current 1-2%.

Now, as enterprises and hyperscalers mull investments in newer, more power-efficient data centers, Apheros is looking to upgrade their existing infrastructure by targeting how they handle the cooling of the specialized hardware powering the AI workloads.

A few years ago, most organizations used heating ventilation and air conditioning (HVAC) to cool down data center servers. The approach worked, but the physics of air cooling is so energy-intensive that these systems could do only so much to keep up with the growing server densities that AI and other modern applications demand.

As an alternative, more capable immersion and on-chip cooling emerged in the market. The former revolves around submerging the servers in a dielectric liquid, while the latter (also known as direct-to-chip cooling) circulates a coolant through cold plates directly attached to the chip.

Since both of these methods are based on the idea of heat exchange where the heat from the chip goes into the liquid and then to another medium (often air or an external cooling system), cooling system vendors use different techniques — such as heat sinks or roughened copper boiler plates — to increase the surface area of the chips and facilitate heat transfer or dissipation when in contact with the cooling medium.

Apheros claims it can make this approach even better with its novel metal foams.

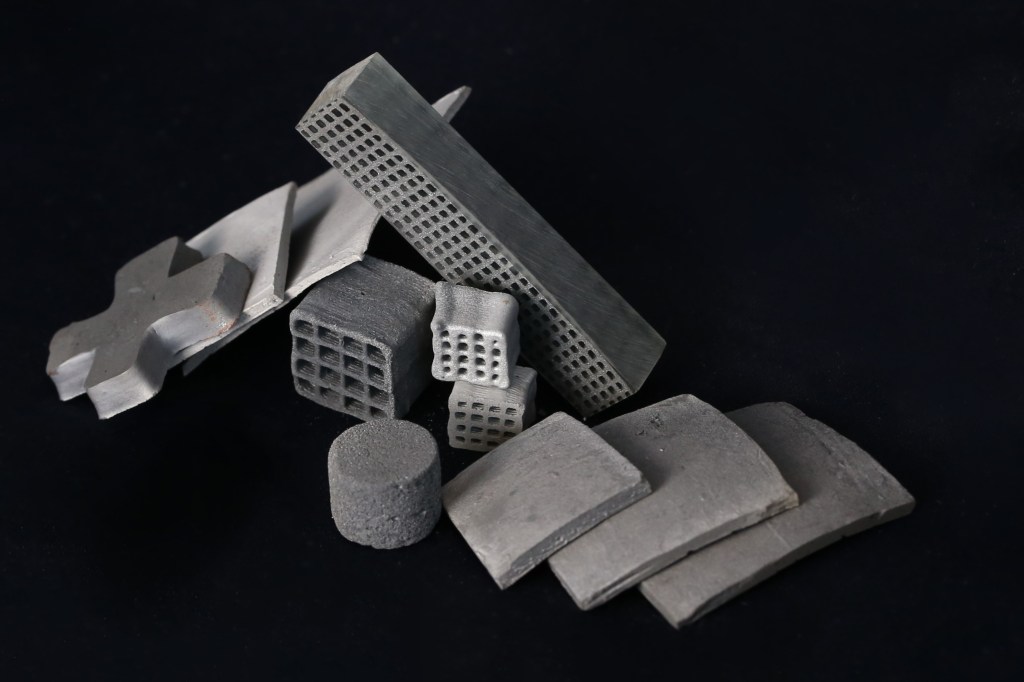

Available as a drop-in replacement for heat sinks and exchangers, the metal foams come with a 1000-fold higher surface area. This, combined with the thermal conductivity and interconnected pore structure of the foams, can provide up to 90% improved heat exchange from the chip to the surrounding liquid.

“This ultra-high surface area metal foam goes directly on the chip and allows the liquid to flow through it. So, in the case of on-chip cooling, it acts like a kitchen sponge with really fine porosity, where the water or the coolant flows through and takes the heat away. This also occurs in immersion cooling,” Julia Carpenter, co-founder and CEO of Apheros, told VentureBeat.

With the foams’ optimized thermal exchange, all the resource-intensive, heat-generating components of the server cool down more quickly, leading to significant energy savings on the cooling front.

“The increase in heat transfer efficiency of Apheros foams directly translates into energy-saving benefits as it allows data centers to use higher coolant temperatures. This is crucial as it allows for heat exchange with outside air without using water-intensive evaporation towers or power-hungry processes like compression. We expect these features of Apheros foams to reduce energy requirements of cooling solutions by 10-20%,” Carpenter explained.

The CEO also pointed out that Apheros’ metal foams are not like others manufactured with investment casting, which are known to suffer from problems such as lack-of-consistency and lack of structural strength, as well as high production costs.

Instead, she said, Apheros uses a different proprietary and patented powder-based manufacturing method at room temperature, which circumvents all known issues while giving users the flexibility to choose the metal best suited for their needs — from copper and nickel to iron and stainless steel.

“It provides consistent properties with innately high open-cell porosity. This is a highly scalable process which is crucial to controlling costs,” she added.

The densities of the foams range between 0.9 and 2.2 g/cm³, allowing easy integration with cooling systems demanding lightweight components.

Early stages of deployment

While the novel metal foams have the potential to accelerate cooling within data centers, it is imperative to note that the technology is yet to see widespread adoption.

Carpenter said that the company is providing the foams to “key” cooling system manufacturers and refining it hand-in-hand based on their feedback. She did not share the names of these buyers.

“We have grown our customer base and increased revenues by a factor of ten from 2023 to 2024. In our customer base, we work with highly innovative corporates with an early adopter mindset and a number of exciting deep tech startups,” the CEO said.

As for the price point, Carpenter noted that the foams make less than 5% of the final price of cooling systems. This signals using these upgraded systems won’t be a major overhead for data center vendors.

Source link